One of the most attractive tiles for the use of the Italian wall tile, such as the NZ ceramic tile, is often manufactured in the form of flat plates in Italy, and may be made of a wide range of materials.

Italy is generally responsible for the production of these tiles.

The clay, sand, and other natural materials occur after they are formed and measured according to specifications and then after each defect is removed, they are heated.

It is possible to use this method for other natural occurring materials.

They come in a number of sizes, and the thickness of each model may vary from three to twenty millimeters at any point, which is a wide range of conceivable measurements throughout the board.

Our good fortune lies in the fact that there are currently manufacturing methods that can be easily found.

In addition to many features in scale and pallet colors, you have an almost unimaginable number of surface treatment, decorative effect and palette color to choose from.

Ceramic tiles are a well-known export of Italy, and these tiles start by carefully selecting raw materials and continue to be manufactured.

The production of ceramic tiles in Italy is one of the most successful exports in the country.

It is possible to clean the ceramic tiles produced in Italy with very little work and in very short time.

When using warm water, the floors and the walls are warm, it is much easier to clean.

In addition, it is a general household cleaner that is without aroma.

ItalianWall Tiles

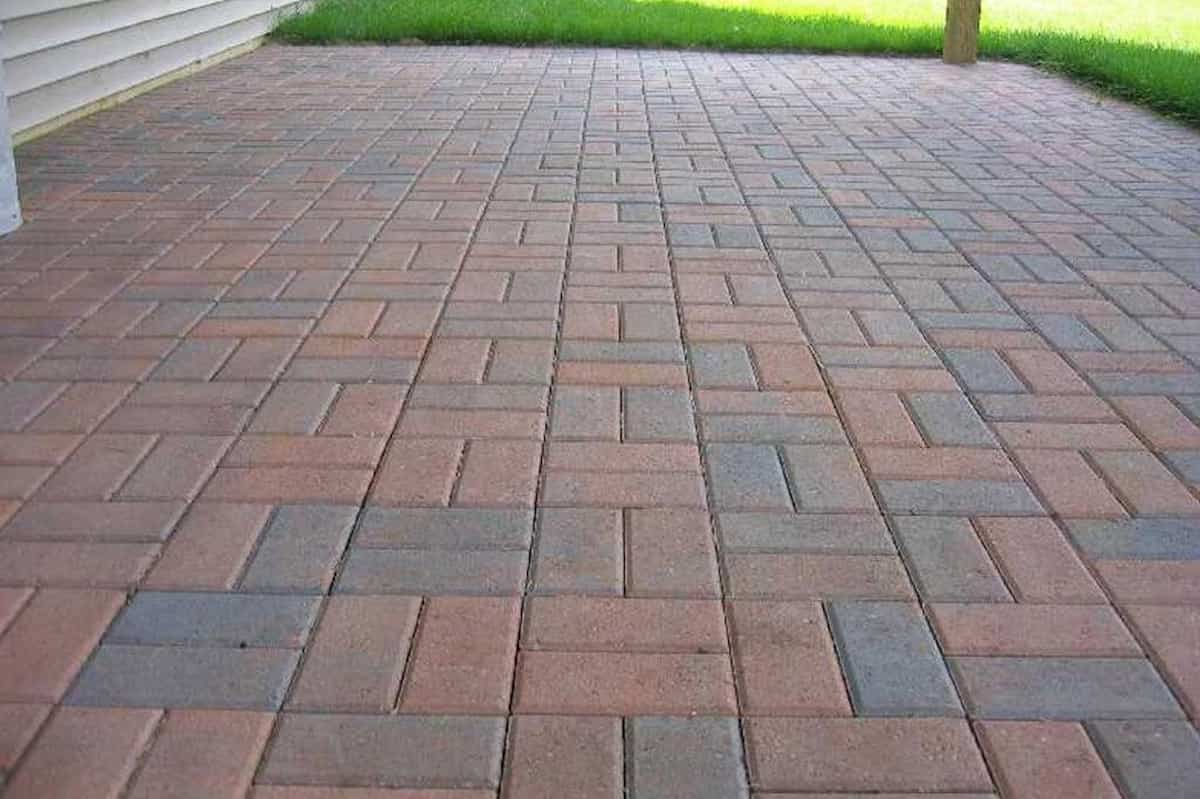

Italian ceramic tiles can be used as excellent surface coating for floors, walls and architectural volumes for designs intended to be executed inside or outside of a building.

These can be done by reinstalling tiles from inside the building or by installing them from the exterior of the building.

It is possible to fulfill these patterns using tiles made in Italy.

Ceramic tiles may be used to cover every surface in the home, regardless of how large or small the surface.

This is because ceramic tiles are so diverse and adaptable.

This is because ceramic tiles might be used for different purposes.

The reason for this is that ceramic tiles offer a high degree of flexibility which explains why this is true.

A range of different items is produced after the raw pieces are pullated and mixed.

This includes clinker, single burning, and two flammings of clay, porcelain, and two flammings.

High-tech ceramic tile production in Italy uses some of the most advanced technology, which is implemented by Italian companies.

Not only are these tiles of extraordinary quality, but they are also made with components that are environmentally friendly.

The high reliability achieved in the production process can be maintained as a direct result of the continuous investments that take place in the automation process.

A quality that is in no way comparable to any of our competitors in any shape, shape or form.

Make changes that are not only creative but also appealing and smell.

Wall Tiles NZ

To know more about tiles used for walls, as NZ_ sit down should be considered that they may be used for a wide range of purposes, Italian tiles are often used for one of the following three programs:

Aesthetics: They are in the interior design project along with other final materials from the start;

Technique: They are able to withstand the pressure that has been created in their environment.

These individuals use these areas without harming the local residents or damaging the ecosystem of the area.

The function of the system shows that it is in good health and can perform its duties successfully.

Feature: It is flexible to a wide range of weather conditions and is not affected by things like foot traffic, fire, freezing temperature, or any other weather.

Antibacterial, photocatalytic, and photovoltaic features have been among the leading causes of recent success.

Wall Tiles Canada

In modern wall tiles, Italian tiles are popular in Canada and around the world.

Despite severe rigidity and densities, ceramics are a substance that has no reaction to other chemicals.

This model offers different advantages compared to many other types of wall material and flooring.

Coating materials are sometimes known as paint or varnish.

Because their composition does not contain cavities, the compact ceramics, especially glazed ceramics, are colorless and have long lifespan when painted.

This feature makes glazed ceramics particularly desirable. Glazing is another technique that may be used for ceramics.

Because of this, the process of tile finishing is a process that is both quick and no complexity in implementation.

In addition to not having dust and dirt on it, it can withstand very low temperatures without damage.

Ceramic tiles, unlike a wide range of other materials, are not flammable and do not produce smoke or other potentially dangerous emissions when burned.

In case of fire, it is recommended that gaseous chemicals and flame retardant be used.

As a result, fire mitigates some of the damage.

Ceramic tiles manufactured in Italy are currently available in different sizes, which comply with the industry’s requirements.

Customers have different choices to choose from, because their lengths vary from a few centimeters to one meter and cm in total.

Ceramics is a non-living substance that cannot be produced because the lifeless nature of the compound with its chemical composition neutralizes it.

producing a variety of chemicals, some of which may be harmful to the environment.

Furthermore, it does not preserve dust, pollen or spores, unlike other surfaces or items.

As a result, cleanliness is a good thing that can reduce health risks.

Kerala Wall Tiles

Wall tiles are used for every home, such as Kerala.

Clay, quartz, and iron minerals are examples of natural raw materials used in the production of ceramic tiles and other ceramic objects.

A large number of natural raw materials are also used.

The extraction process of these raw sources is carried out in a way that does not compromise the ecosystem or environment nearby.